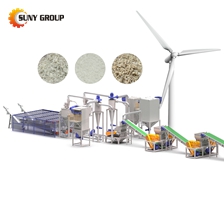

Wind Turbine Blade Recycling Machine

-

Wind turbine blade recycling machine is designed to efficiently process and recycle decommissioned wind turbine blades. It utilizes advanced cutting, shredding, and separation technologies to break down the blades into reusable materials, such as fiberglass and resin. This equipment plays a crucial role in promoting sustainability by reducing landfill waste and supporting the circular economy, ensuring that valuable materials are recovered and reused in various industries, contributing to eco-friendly waste management in the renewable energy sector.

Overview

The recycling of wind turbine blades faces significant challenges, mainly due to the materials used, such as glass fiber and carbon fiber reinforced polymers, which are difficult to process. To address this issue, SUNY GROUP has developed a blade recycling production line that effectively separates and recycles the glass fiber, resin, balsa wood, and other materials found in wind turbine blades.

The final products include resin powder, small-sized fiber bundle, large-sized fiber bundles,and balsa wood.

Gallery

Working Process

1.Double shaft Shredder: The process of coarse crushing requires a double-shaft shredder to shred the material.

2.The hammer crusher can further break down wind turbine blades, with a screen used to control the size of the output, making it easier for the next step in the separation process.

3.Three-stage sorting: 95% Sorting Rate. After the wind turbine blades are cut, they enter the recycling production line, where the materials undergo three stages of crushing and three different separation processes.The final products include resin powder, small-sized fiber bundle, large-sized fiber bundles, and balsa wood.

4.Pulse Dust Collector: The production line is equipped with 2 pulse dust collectors, which have high dust removal efficiency and can capture dust particles larger than 0.3 micrometers with an efficiency of up to 99%.

5.Utilizing PLC control: Continuous feeding, intelligent operation,automatic alarms, bilingual interface, easy and efficient operation, ensuring stable equipment operation.

Features

1.Through our company wind turbine blade recycling techniques, materials such as resin, glass fibers, and others can be separated and reused, minimizing resource waste and reducing environmental impact.

2.Recycling wind turbine blades not only helps in reducing waste but also allows the recovered materials to be repurposed in industries like construction and composite manufacturing, promoting resource circularity and supporting sustainability goals.

Sepcifications

| Model | Capacity | Power | Size(m) |

| ZY-W-1T | 1-1.5 t/h | 463kw | 40*20*5 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Wind Turbine Blade Recycling Machine

Wind Turbine Blade Recycling Machine