Waste Motor Recycling Machine

-

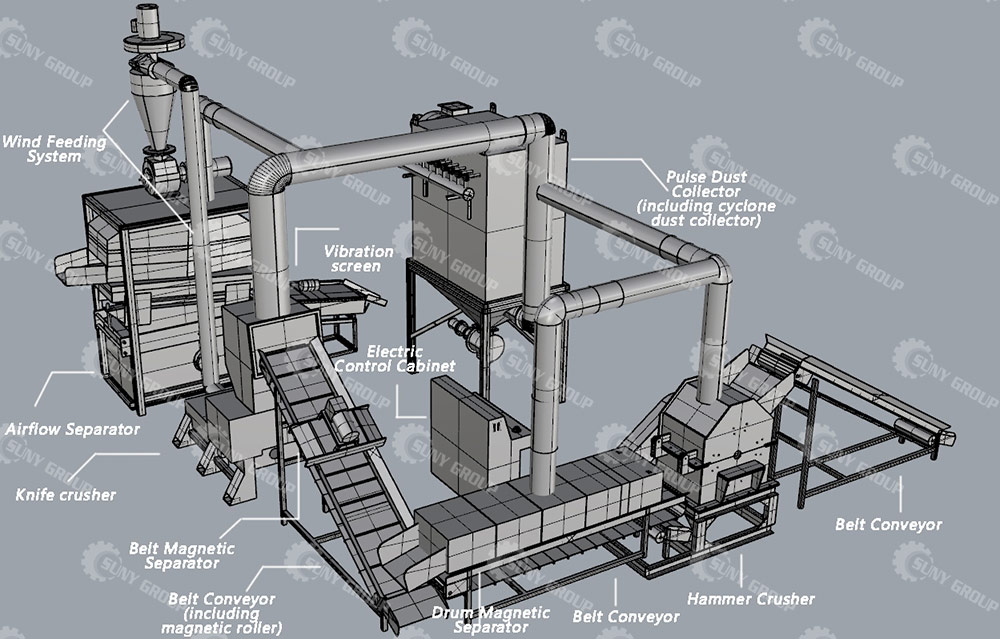

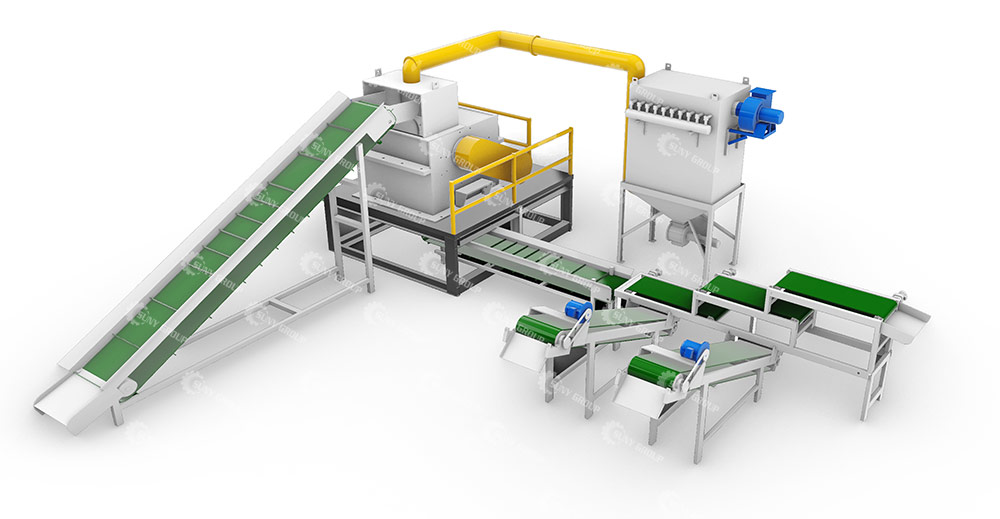

The scrap motor rotor recycling machine is designed to efficiently process and recover valuable materials from used motor rotors. It uses advanced crushing, shredding, and separation technologies to extract copper, aluminum, and other metals from the rotor components. This motor recycling machine contributes to sustainable recycling by maximizing material recovery, reducing waste, and minimizing environmental impact, making it essential for the recycling of electric motors and promoting resource conservation.

Overview

The scrap electric motor recycling machine is an ideal equipment for recycling motor stators, circuits, small transformers, etc. with a diameter of less than 20cm. This scrap motor recycling machine can efficiency separate and recycle the value metal from scarp motor.

Gallery

Working Process

The scrap electric motor recycling machine mainly includes metal hammer crusher, knife crusher, magnetic separator, air separator, pulse dust collector and other accessory machines. After processing, you can get copper, iron and non-metal.

Features

1.The scrap motor recycling machine is energy-efficient, automated, and easy to operate.

2.Provide customers with customized recycling solutions and offer technical and equipment support.

Sepcifications

| Model | Capacity | Power | Weight | Size(m) |

| MR-1000 | 1t/h | 177kw | 26.5ton | 25x6x6 |

| MR-2000 | 2t/h | 303kw | 47ton | 40x6x6 |

| MR-3000 | 3t/h | 345kw | 50.5ton | 45x6x6 |

| MR-5000 | 5t/h | 493kw | 67.5ton | 50x10x6 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Waste Motor Recycling Machine

Waste Motor Recycling Machine

Waste Motor Dismantling Machine

Waste Motor Dismantling Machine

Horizontal Metal Hammer Crusher

Horizontal Metal Hammer Crusher

Double Shaft Shredder

Double Shaft Shredder

Eddy Current Separator Machine

Eddy Current Separator Machine