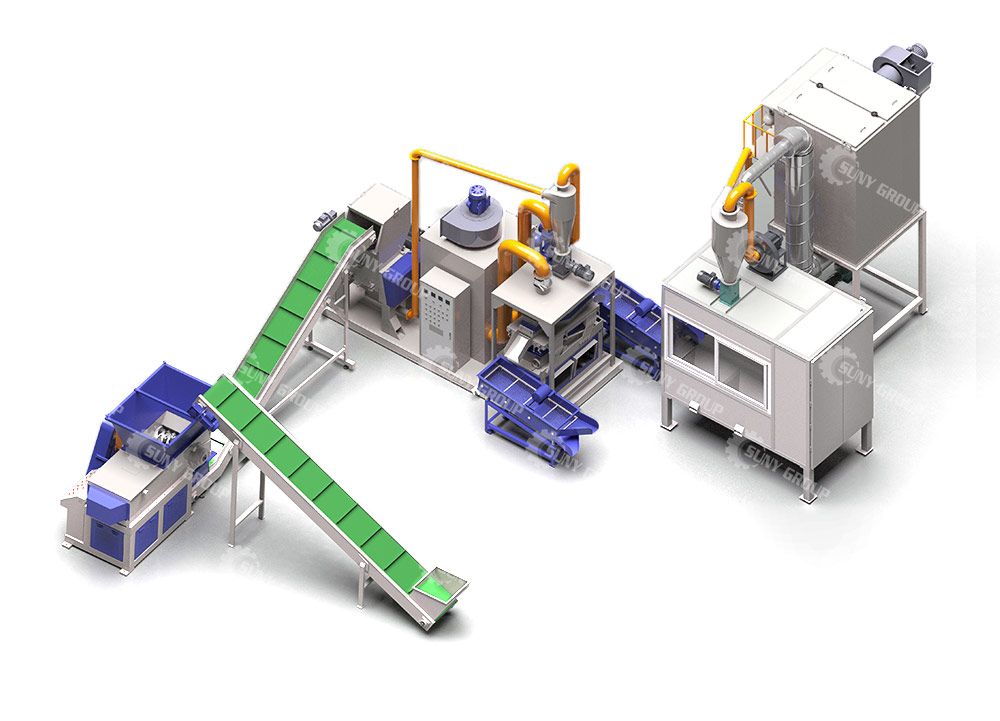

Waste Cable Wire Recycling Plant

-

The waste copper wire recycling machine is designed to efficiently process and recover valuable metals from discarded electrical wires. It uses advanced shredding, separation, and sorting technologies to extract copper, aluminum, and other metals from the insulation. This equipment maximizes material recovery, reduces waste, and promotes environmental sustainability by recycling metals for reuse, making it an essential tool for the efficient and eco-friendly management of scrap electrical wires.

Overview

This copper wire recycling plant use dry type recycling method, mainly used to recycle most kinds of waste copper wire, the copper wire will be separated into copper particles and plastic particles. The copper wire recycling machine can recycle the copper wire which diameter is 0.3mm-20mm.

This machine can recycle different various types of waste copper cable wires, such as: automobile electrical wire, the electric wire of car, motorcycle electric wire computer case wire and communication cable, etc.

Suitable for recycling most kinds of copper wire.

Get copper particles and plastic particles

Gallery

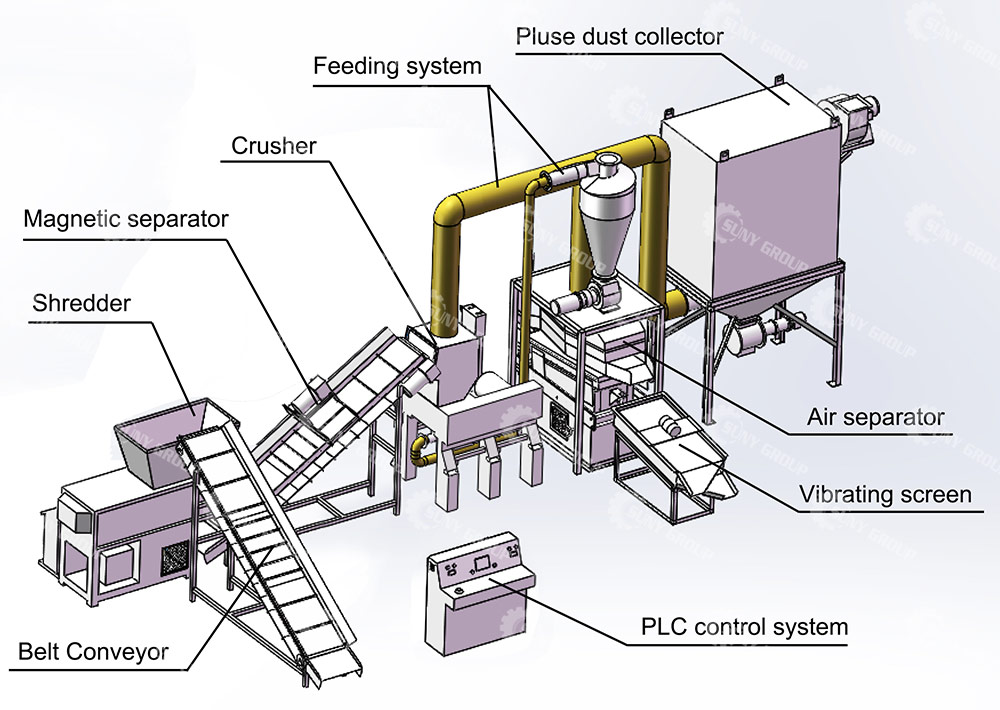

Working Process

1. Put wasted cable wire into the crusher machine, they will be cut into granules firstly. During this process, copper and plastic are separated but still mixed together.

2.Then the granules are sent to air separator for separation process, according to the gravity difference and through air blow, the copper and plastics are separated success sully and comes out from different sides.

3. At last we collect the separated pure copper and plastic..

Features

1.Compact structure and reasonable layout, safe and reliable, easy to install.

2.Controlled by PLC. Continuous feed, intelligent operation, automatic alarm make it easy to operate and save your time and energy, to ensure the stable operation of the equipment.

3.No dust outlet, the dust separation rate can reach up to 99%.

4.The blade and screen adopts special wear resistance and high toughness alloy material, which improve the service life and reduce the production cost.

Sepcifications

| Model | Capacity | Weight | Size(m) | Power |

| CR-200 | 100-200kg/hr | 1800kg | 1.8*1.8*2.5 | 20kw |

| CR-300 | 200-300kg/hr | 3700kg | 4.5*2.5*4.0 | 55kw |

| CR-500 | 400-500kg/hr | 7500kg | 6*3*4.0 | 105kw |

| CR-1000 | 800-1000kg/hr | 15000kg | 20*10*4.5 | 195kw |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Waste Cable Wire Recycling Plant

Waste Cable Wire Recycling Plant

Mini Copper Wire Granulator

Mini Copper Wire Granulator

Scrap Cable Stripping Machine

Scrap Cable Stripping Machine

ACSR Cable Recycling Machine

ACSR Cable Recycling Machine