-

-

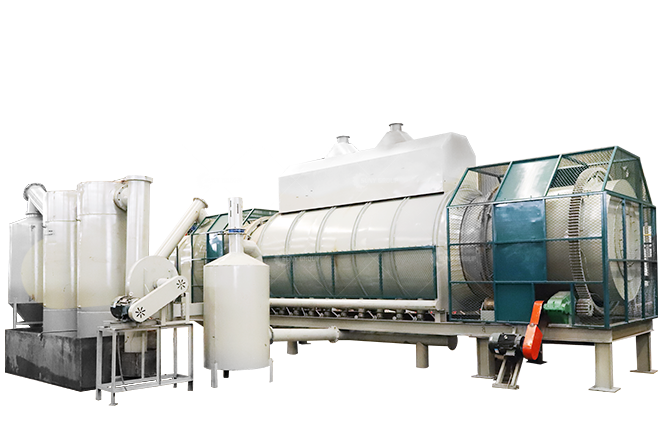

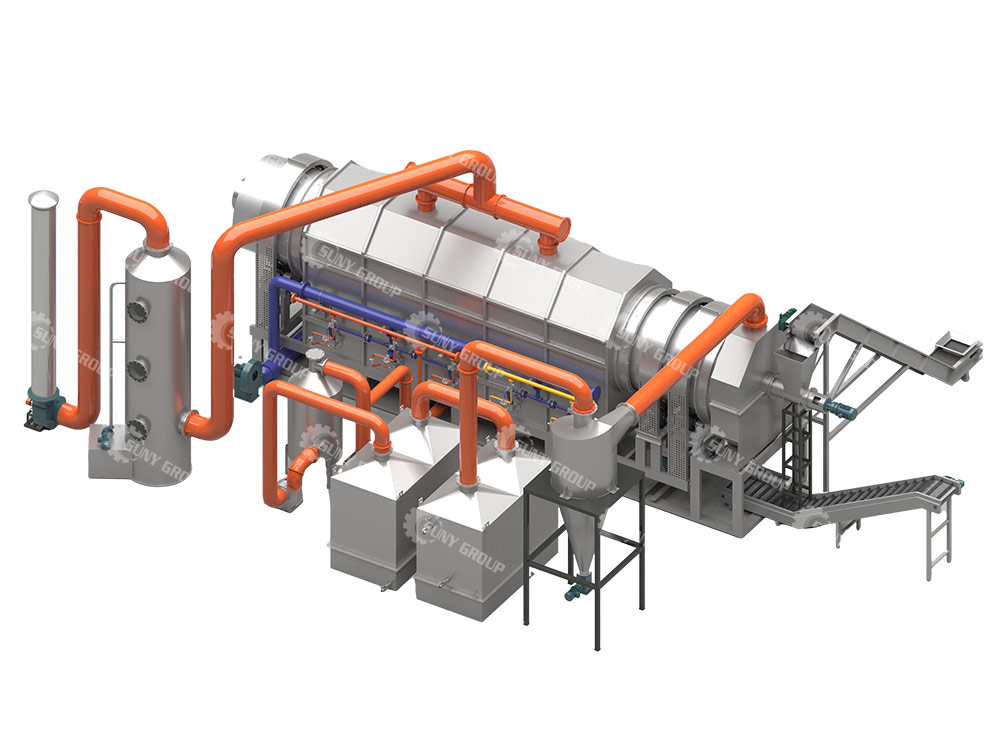

UBC Decoating Furnace

The UBC (Used Beverage Can) decoating furnace is designed to remove coatings, inks, and contaminants from used beverage cans (UBCs) during the recycling process. It operates at high temperatures, efficiently burning off the coatings while preserving the metal’s integrity. This machine enhances the quality of recycled aluminum, making it suitable for reuse in manufacturing. Its robust design, energy efficiency, and precise temperature control ensure reliable and eco-friendly operation for metal recycling facilities.

Video

Overview

This Continuous UBC Cans decoating machine is designed to efficiently remove coatings and paints from used beverage cans before they are melted down for recycling. The decoating process not only improves the quality of the recycled aluminum but also enhances the energy efficiency of the recycling process by reducing the amount of energy required during the melting phase.

The purpose of carbonization paint removal of cans: to remove 2-3% of organic paint layer and sugar stains, moisture, dust and other impurities.

Gallery

Features

1.Improving aluminum alloy quality: Carbonizing and removing the paint effectively removes the paint and impurities on the surface of aluminum cans, preventing harmful impurities and gases from entering the molten aluminum during direct smelting. This ensures that the aluminum alloy meets quality standards for reuse, avoiding economic losses.

2.Protecting the environment and workers’ health: Carbonizing the paint reduces the emission of harmful gases during combustion, helping to minimize environmental pollution and safeguard the health of workers.

3.Enhancing recycling efficiency: By removing the paint through carbonization, it prevents oxidation of the aluminum during paint combustion, thereby improving the aluminum recovery rate, reducing fuel consumption, and boosting overall recycling efficiency.

Sepcifications

| Model | Capacity (Cans) (kg/h) | Size (mm) | Power (kw) | Weight (t) |

| UBC-1500 | 800-1000 | 11800*2000*2450 | 33.5 | 16 |

| UBC-1800A | 1500-2000 | 11800*2200*2650 | 42 | 18.5 |

| UBC-1800B | 1500-2000 | 11800*2200*2650 | 45.5 | 21.5 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

UBC Decoating Furnace

UBC Decoating Furnace

Horizontal Metal Hammer Crusher

Horizontal Metal Hammer Crusher

Double Shaft Shredder

Double Shaft Shredder