-

-

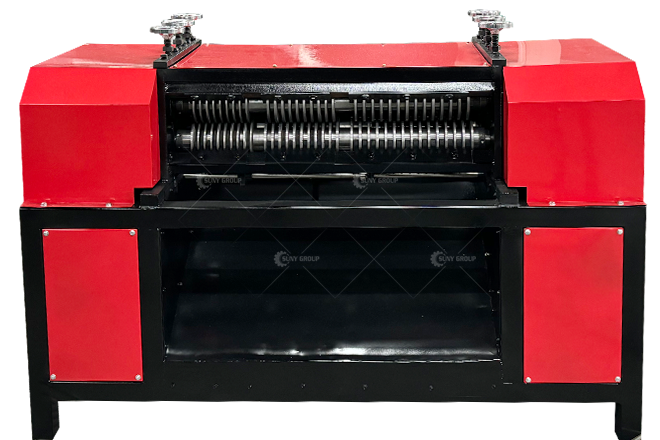

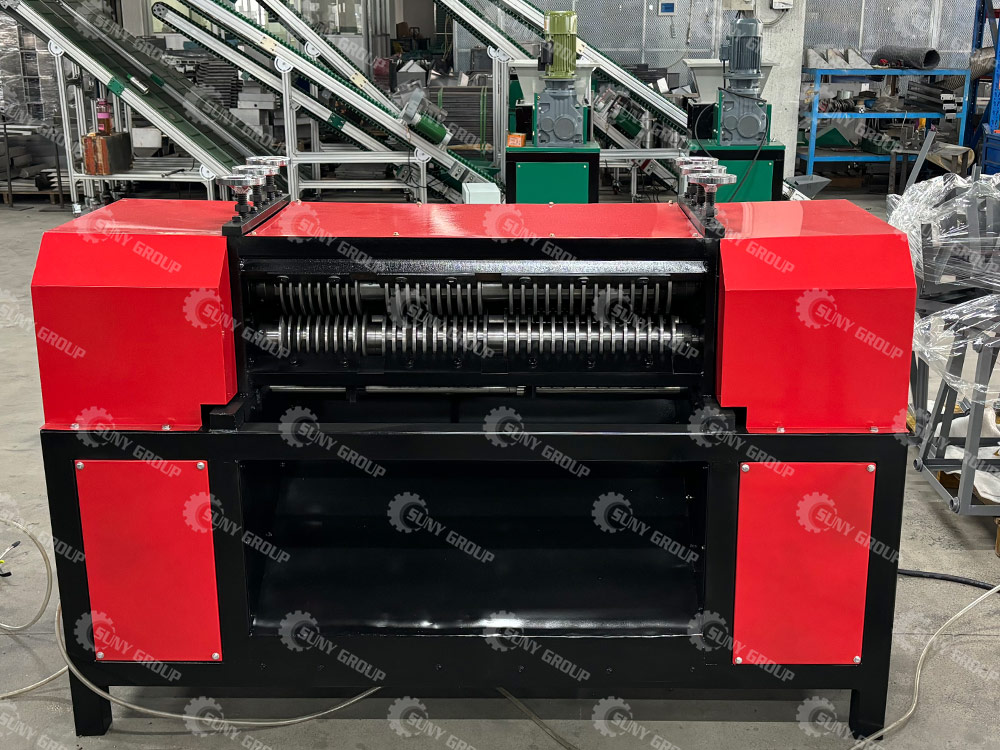

Scrap Radiator Stripping Machine

The scrap radiator stripping machine is designed to efficiently separate the metals in scrap radiators, typically copper and aluminum. It uses advanced mechanical methods to strip off the outer aluminum layer, leaving the copper core intact for further recovery. This equipment ensures high material recovery rates, reduces waste, and supports sustainable recycling practices by efficiently processing radiators for valuable metals, contributing to resource conservation and environmental sustainability in the recycling industry.

Video

Overview

Scrap radiator stripping machine is a professional stripping machine for the scrap AC radiator, water tank radiator etc recycling. This machine can handle the single layer and double layer radiator. Before making machine for you, please let us know your raw material very well.

The radiator stripping machine is a professional stripping machine for the scrap AC radiator, water tank radiator etc recycling. And get the copper and aluminum . When processing, the input width of the radiator is about 30-40cm, then input the material, the machine will finish stripping , get the output automatically. The machine is much suitable for the single layer copper pipes, normally , the machine can process three different range radiator: 19 mm,21 mm, 25 mm; for multi-layer radiator, it is better use a saw separate first.

Gallery

Features

1.Simple structure, high processing rate, stable operation;

2.No loose of the aluminum & copper;

3.Low Investment, good profit;

4.Three different range size for the radiator.

Sepcifications

| Size(MM) | Power(Kw) | Weight(Kg) |

| 1750*1000*1200 | 7 | 700 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Scrap Radiator Recycling Machine

Scrap Radiator Recycling Machine

Scrap Radiator Stripping Machine

Scrap Radiator Stripping Machine