Scrap Radiator Recycling Machine

-

AC radiator recycling machine is designed to efficiently separate and recover valuable metals from scrap radiators. The equipment uses advanced technologies such as shredding, crushing, and air separation to extract copper and aluminum from the radiator’s components. It ensures high recovery rates, minimizes material waste, and supports sustainable recycling practices. By reclaiming precious metals, this equipment promotes resource conservation and reduces environmental impact, contributing to the circular economy in the recycling of automotive and industrial components.

Overview

Scrap ac radiator recycling machine can processing all kinds of large blocks of radiator(copper and aluminum water box) or motor rotor(with axle)≤15cm. Copper and aluminum can be separated by this equipment.

Successful development of the radiator machine, greatly liberate the productive forces, improve the metal recycling quality. The most important, it solves the problem of dust overflow effectively, reducing the pollution to air.

Raw Materials All kinds of large blocks of radiator(copper and aluminum water box)

Final Products: Copper Aluminum lron

Gallery

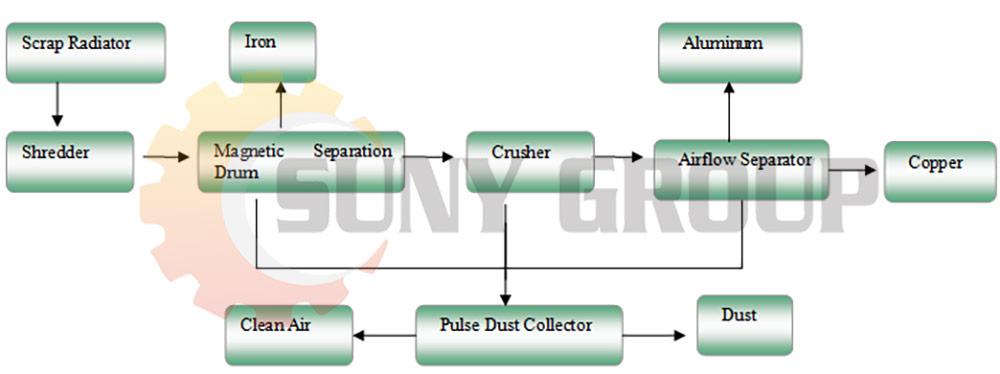

Working Process

Features

1.The entire ac radiator recycling machine adopts PLC control, ensuring the equipment operation stability.

2.The first gravity separation and the second air flow separation make the separation rate up to 99%.

3.Pulse dust removal system inhibits the dust overflow in 99% efficiency, no secondary pollution.

Sepcifications

| Model | Weight (ton) | Capacity (kg/h) | Sorting Efficiency | Dust Removing Efficiency | Power (kw) |

| SR-500 | 13 | 400-500 | >98% | 99% | 139 |

| SR-1000 | 18 | 800-1000 | >98% | 99% | 205 |

| SR-2000 | 22 | 1500-2000 | >98% | 99% | 328 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Scrap Radiator Recycling Machine

Scrap Radiator Recycling Machine

Scrap Radiator Stripping Machine

Scrap Radiator Stripping Machine

Horizontal Metal Hammer Crusher

Horizontal Metal Hammer Crusher

Double Shaft Shredder

Double Shaft Shredder

Eddy Current Separator Machine

Eddy Current Separator Machine