Scrap Metal Crushing Recycling Machinery

-

The scrap metal crushing recycling machinery can crush scrap metal into particles and, at the same time, use a magnetic separator to separate steel from copper, aluminum, plastic, and other materials. According to customer requirements, we can also provide solutions to further separate materials such as copper, aluminum, and plastics. Finally, pure steel, copper, aluminum, plastic, and other materials are obtained. For steel scraps recycling, we will provide a one-stop solution service.

Overview

SUNY GROUP scrap metal crushing recycling machinery is customized equipment. According to your raw materials and recycling capacity requirement, SUNY GROUP can customize various recycling lines for you. The metal crusher machine is mainly used in large waste recycling stations, waste metal recycling companies, etc.

The scrap metal crusher recycling machinery can crush steel scraps, car shell, waste bicycles, motorcycles, waste wires, cans, beer bottle caps, tin boxes, paint buckets and other metals into ideal particles, thus greatly good for transportation and saving transportation costs. Users can choose different models and configurations according to their raw materials to be processed and the requirements for finished materials (broken particle size).

Suitable for various types of scrap metal materials:

The scrap metal after crushing and recycling :

Gallery

Working Process

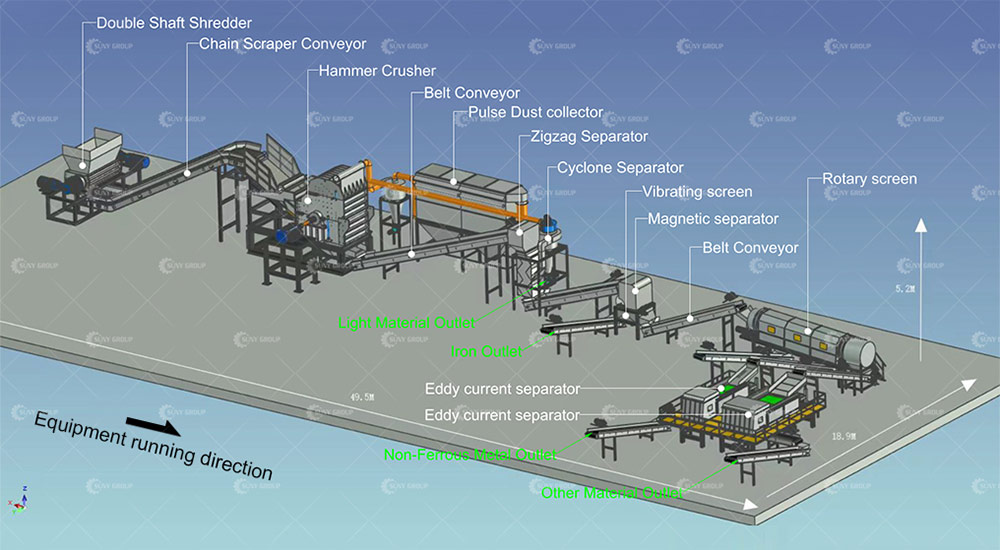

1. Material Feeding: The raw materials are loaded onto a chain-type conveyor, which transports them steadily into the shredder.

2. Primary Shredding: The shredder breaks the materials into large pieces, making them suitable for further processing.

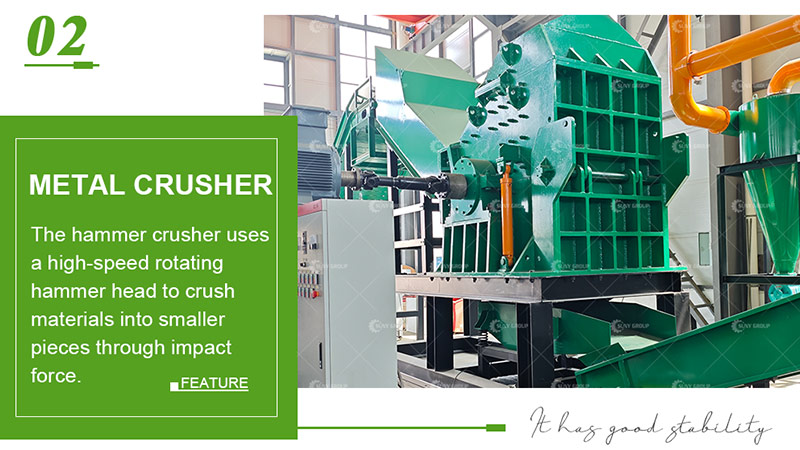

3. Secondary Crushing: The shredded materials are then transferred via conveyor to a hammer crusher,where they are crushed into smaller, uniform particles.

4. Dust Collection: A dust collection system operates simultaneously to capture dust generated during the crushing process, ensuring a clean and environmentally friendly operation.

5. Magnetic Separation: The crushed material passes through a magnetic separator, which removes ferrous metals (iron)from the material stream.

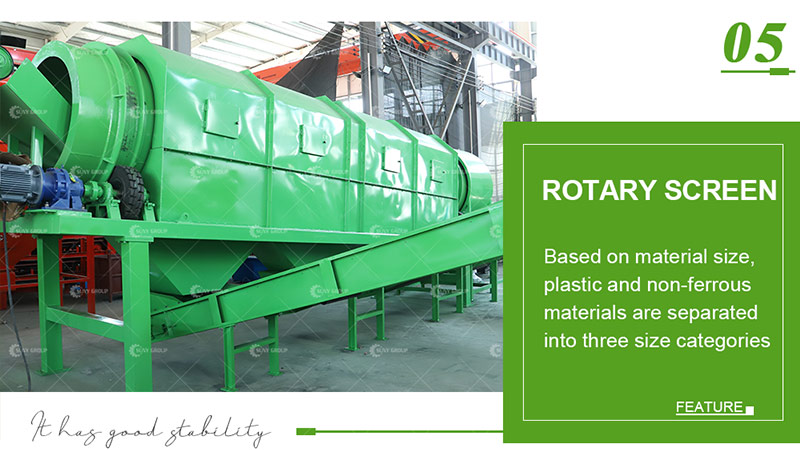

6. Rotary screen: The remaining non-ferrous and plastic mixture is conveyed into a rotary screen, which separates the material into three different size categories, each discharged from a separate outlet.

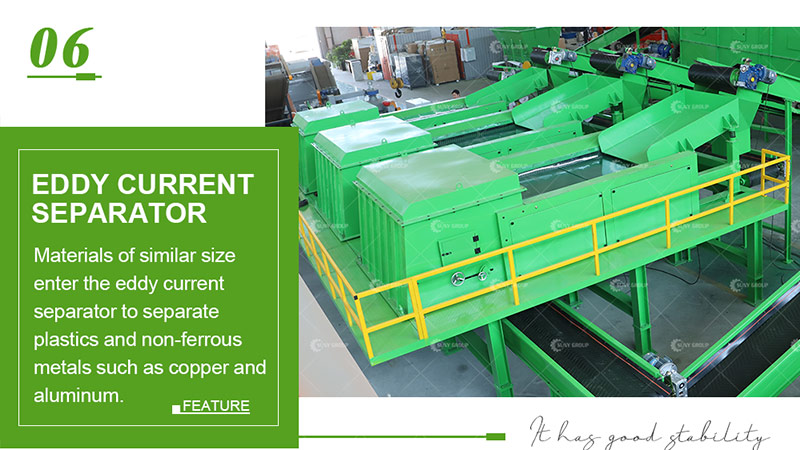

7.Eddy Current Separation: Each of the three size-based outputs is fed into a dedicated eddy current separator, which effectively separates non-ferrous metals (like aluminum and copper) from plastic.

Features

1. SUNY GROUP provide customers with customized scrap metal recycling solution.

2. All the machines are full automatic and easy operation.

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Horizontal Metal Hammer Crusher

Horizontal Metal Hammer Crusher

Double Shaft Shredder

Double Shaft Shredder

Eddy Current Separator Machine

Eddy Current Separator Machine