-

-

PCB Dismantling Machine

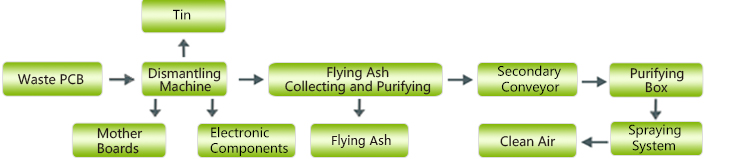

The PCB dismantling machine is designed to safely and efficiently separate components from electronic circuit boards. Using advanced automation, it removes metals, plastics, and other materials without damaging valuable parts. This equipment is essential for e-waste recycling, enabling the recovery of precious metals and promoting sustainable resource management.

Video

Overview

PCB Components Dismantling Machine is used to remove the electronic components on different PCB boards, The drum made of 6mm thickness #45 steel and its own special technology, which have the characteristics of high temperature resistance abrasion resistance, safety and reliable, stable performance, high precision, durability.

Gallery

Features

1. Full automatic working, save labor.

2.Tin remove and dismantling components at one step.

3. Automatic temperature controlled by heating system.

4. Different capacity: 200kg/h,300kg/h,500kg/h.

5. Operating safety and easily.

6. Less damage to the components, keep the precious metals no losing.

7. Mother board and components can be proceed respectively in the next step to improve economic benefits.

8. Friendly to the air environment, all the smoke processing by the waste gas treatment system

Sepcifications

| Model | Capacity | Power(kw) | Weight(kg) | Size(m) |

| ECD-200 | 200kg/h | 4.85 | 450 | 1.67*0.97*1.4 |

| ECD-500 | 500kg/h | 6.75 | 1100 | 2.1*1.27*1.74 |

| ECD-1000 | 1000kg/h | 11 | 2180 | 2.74*1.83*2.43 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

E Waste Recycling Plant

E Waste Recycling Plant

PCB Dismantling Machine

PCB Dismantling Machine

Precious Metal Refine Plant

Precious Metal Refine Plant

Gold Stripping Equipment

Gold Stripping Equipment