Paper Plastic Recycling Plant

-

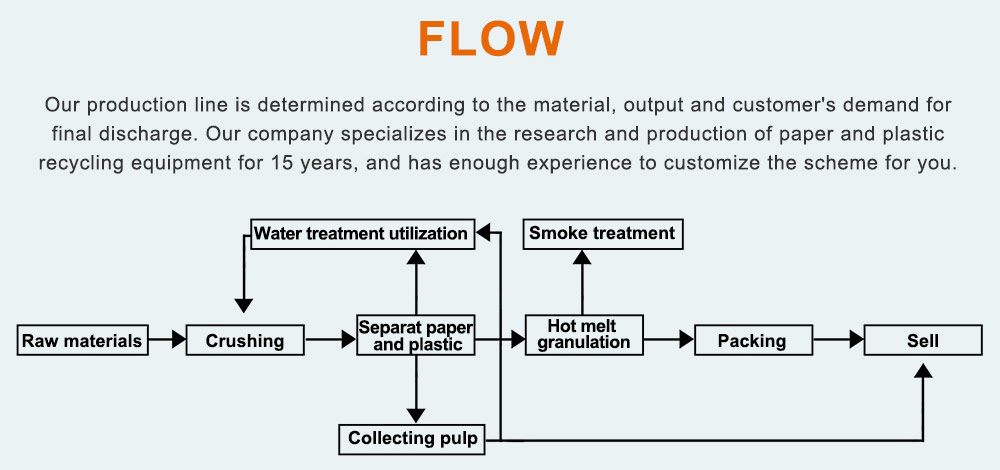

Paper plastic recycling equipment is designed to efficiently separate and recover materials from paper plastic composites, commonly found in packaging. It uses advanced mechanical and separation technologies, such as shredding, air separation, and screening, to extract paper and plastic components. This equipment promotes sustainable recycling practices, reduces environmental impact, and supports the circular economy by enabling the reuse of valuable materials, contributing to eco-friendly waste management and resource conservation in the packaging and recycling industries.

Overview

Paper plastic recycling equipment is mainly used to recycle various paper-plastic composite materials, such as: Coated paper, Kraft paper bag, Tetra pak, combibloc, and other paper-plastic composite materials. This machine has wide application in the paper recycling & plastic recycling industry.

Gallery

Working Process

The paper-plastic sorting plant includes Four Main Single Machines(As your demands)

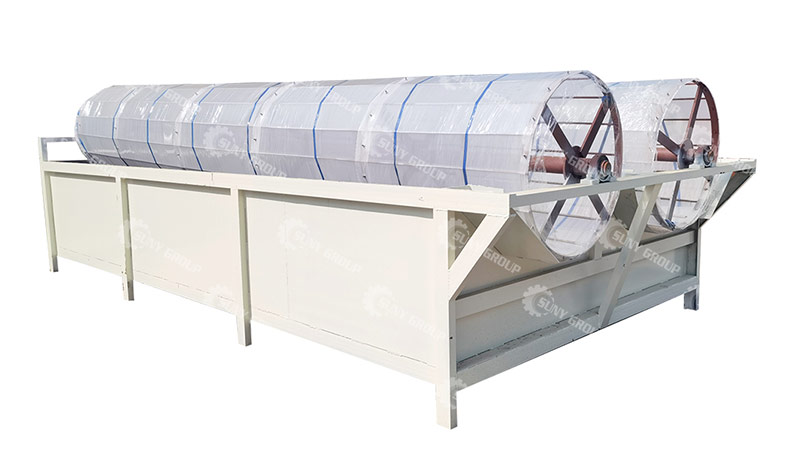

1.Paper Aluminum Separator:

Paper aluminum separator is the main equipment of the whole paper-plastic recycling production line. The working principle is that the motor drives the spindle to rotate at high speed. The spindle blade drives the material to move from the feeding end to the discharging end.

2.Pulp Filter:

In the pulping of waste paper, because of the different paper quality of waste paper, there is a large amount of slag. This machine can remove light and heavy sundries and decompose small pieces of paper in fibers, without blocking the sieve plate, and hard sundries will not hurt the sieve plate.

3.Pulp Dehydrator:

The basic working principle of the pulp dehydrator is: the particles rotate to a certain height with the drum,are thrown and fall by gravity, and are filtered through the screen to form a sieve.

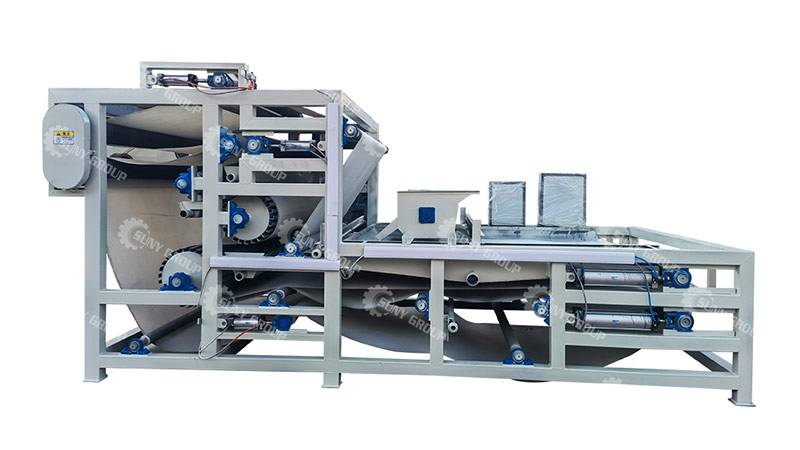

4.Pulp Filter Press Equipment:

The pulp filter press uses the motor to drive the spindle to run and drive the polyester blanket. The pulp is transported to the filter press by the pump and evenly flows onto the polyester blanket. After being driven by the polyester blanket, it is squeezed between two layers of polyester blankets, and then squeezed and compacted by multiple pressing rollers, thus making cardboard for secondary utilization.

Features

1.Efficient Separation: Separates paper and plastic materials effectively, even in complex composites.

2.High Recovery Rates: Maximizes the recovery of valuable materials for reuse.

3.Reduced Manual Labor: Automation minimizes human involvement, improving efficiency and safety.

4.Environmental Impact Reduction: Reduces landfill waste and prevents environmental pollution.

5.Sustainable Recycling: Supports eco-friendly recycling practices, contributing to a circular economy.

6.Resource Conservation: Recovers reusable materials, conserving natural resources.

7.Versatility: Capable of processing various paper-plastic composite materials..

8.Cost-Effective: Reduces costs by improving operational efficiency and material recovery.

Sepcifications

| Model | Power(kw) | Capacity | Size(m) |

| PPR – 1000 | 430 | 800-1000KG/H | 33*14*5 |

| PPR – 3000 | 670 | 2500-3000KG/H | 44*14*5 |

| PPR – 5000 | 1190 | 4500-5000KG/H | 40*30*5 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Paper Plastic Recycling Plant

Paper Plastic Recycling Plant