-

-

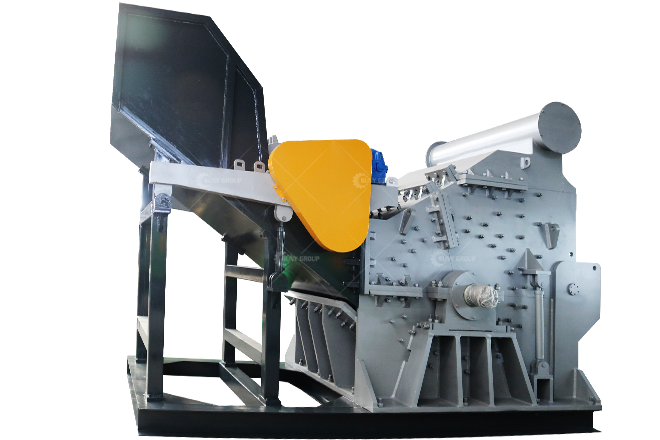

Horizontal Metal Hammer Crusher

The horizontal metal hammer crusher is designed for crushing various metal materials, including scrap metal, steel, and aluminum. It features a horizontal rotor equipped with heavy-duty hammers that efficiently break down materials into smaller, manageable pieces. This equipment offers high throughput, low energy consumption, and reliable performance. It is ideal for recycling metal waste, reducing material volume, and supporting sustainable practices in scrap metal processing industries.

Video

Overview

The heavy duty horizontal metal hammer crusher is mainly used in large waste recycling stations, waste metal recycling companies, etc. Users can choose different models and configurations according to their raw materials to be processed and the requirements for finished materials (broken particle size).

Gallery

Metal hammer crusher is widely used in crushing limestone, glass, batteries, gypsum, aluminum oxide, tungsten carbide, scrap metals, scrap motors, copper aluminum radiator, broken bridge aluminum, aluminium alloy, e waste, hard plastics, metal cans, etc.

Features

1. Metal hammer crusher characterized by high crushing ratio, compact size, strong production ability, uniform product size, less powder rate, low energy consumption, simple structure, light weight, easy operation and maintenance;

2. Hammerhead material selection is very important, ordinary carbon steel hammerheads will wear off in a very short time, but with the hammer high manganese steel casting, heat treatment, surface hardening it, you can use a long time. The hammerhead materials and design used is ZGMn13 high manganese steel, a material with high wear resistance, and can withstand shock loads, suitable as hammer.

Sepcifications

| Model | Size(MM) | Power(Kw) | Weight(KG) | |

| HC-900 | 3000*2020*3170 | 75 | 4460 | |

| HC-1200 | 3300*1500*4450 | 110 | 8000 | |

| HC-1400 | 4880*2140*5150 | 200 | 27800 | |

| HC-1600 | 5200*2450*5600 | 280 | 32000 | |

| HC-1800 | 5560*2500*5280 | 480 | 40000 | |

| Working Voltage:380V, 415V ,440V or can be customized. (If you want more detailed parameters and quotations, please contact us) | ||||

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -