-

-

Eddy Current Separator Machine

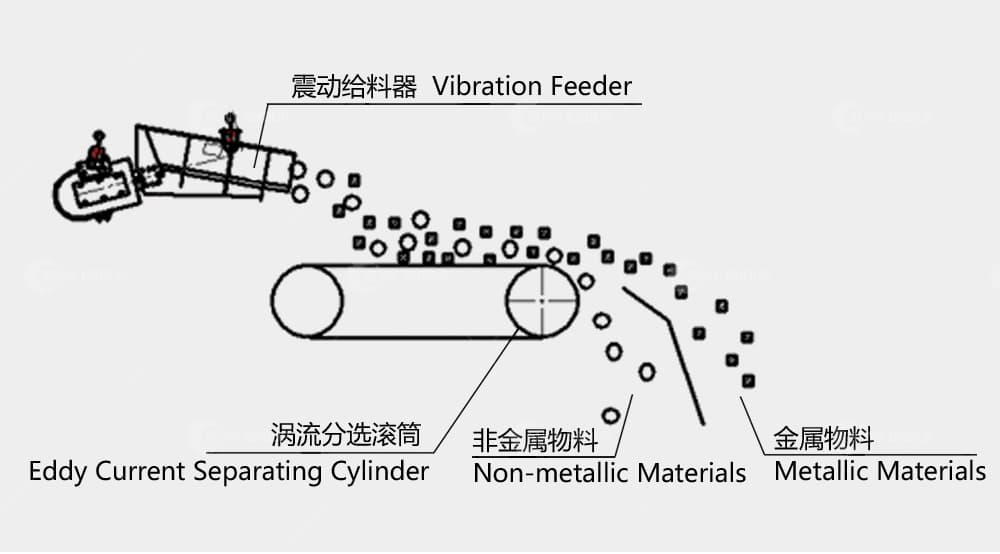

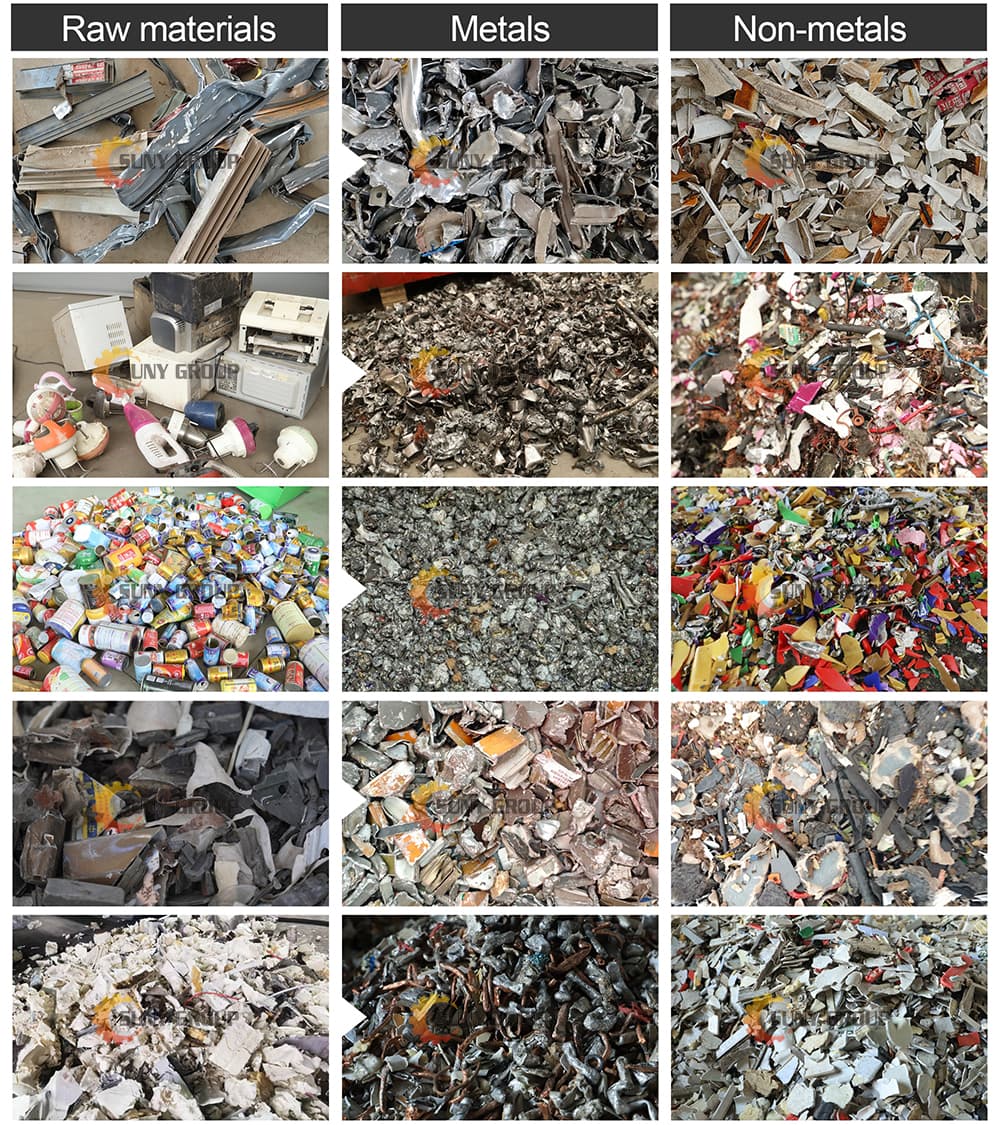

The eddy current separator is a specialized machine used to separate non-ferrous metals, such as aluminum and copper, from mixed waste materials. It works by generating a strong magnetic field that induces eddy currents in the metals, causing them to be repelled and separated from other materials. Widely used in recycling plants, this equipment offers high sorting efficiency, stable performance, and low maintenance. It greatly improves metal recovery rates and supports efficient waste processing.

Video

Overview

The eddy current separator is an advanced sorting machine designed to recover non-ferrous metals such as aluminum, copper, and zinc from mixed waste streams.

It uses a high-speed magnetic rotor to create eddy currents, which generate repulsive forces that separate non-ferrous metals from non-metallic materials. This equipment is widely used in recycling facilities, especially in electronic waste, municipal solid waste, and metal recycling lines.

Gallery

Features

1. Simple operation, automatic separation of metal and nonmetal; Reliable single power supply design makes the system compact and reliable;

2. The span of separable metal particles is large, which is usually between 3mm and 100mm;

3. The installation is convenient, customized according to customer’s requirements, and can be effectively connected with newly-built and existing assembly lines;.

4. High gradient rare earth permanent magnet system is used with low energy consumption and convenient maintenance;

5. Materials with different particle sizes can be sorted according to the different turning directions of the rotors;

6. a variety of models to choose from ( trau wodtj range of 300mm to 1500mm ).

Sepcifications

| Model | Power | Weight | Dimensions L*W*H |

|---|---|---|---|

| ZYEC2000 | 10 Kw | 2800 Kg | 5000*2270*2600 mm |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Eddy Current Separator Machine

Eddy Current Separator Machine