PCB Circuit Board E waste Recycling Plant

-

The e waste recycling plant is designed for the recycling process of various e-waste. It combines crushing, shredding, and advanced sorting technologies to separate valuable materials. This automated system ensures high recovery rates, reduces environmental impact, and promotes sustainable e-waste recycling. SUNY GROUP have rich experience in the e waste recycling solution. We can provide customized e waste recycling solution.

Overview

PCB circuit board electronic waste recycling equipment is used to separate scraps of waste circuit board motherboards, copper clad boards, circuit boards, mixed metal and non-metallic materials. The final product is metal powder and fiber powder.

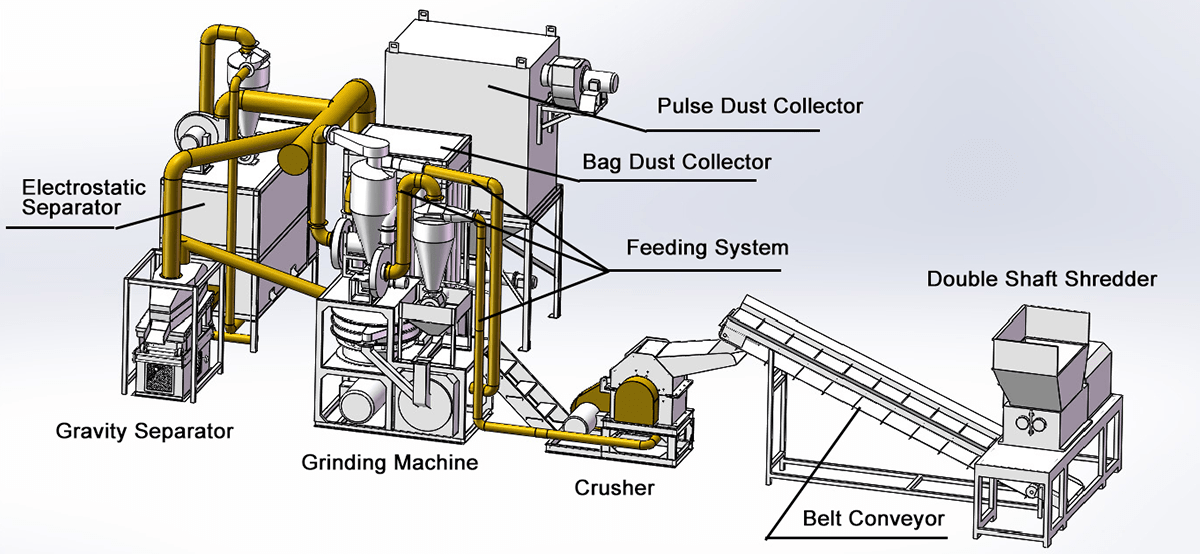

The E waste recycling equipment mainly adopts physical crushing and sorting technology. The PCB circuit board e waste recycling machine consists of shredding system, milling system, sorting system and dust collection system, the whole process of our circuit board recycling production line is controlled by PLC.

If you want to recover precious metals from waste circuit boards, you can consult the matching circuit board disassembly machine and precious metal extraction equipment.

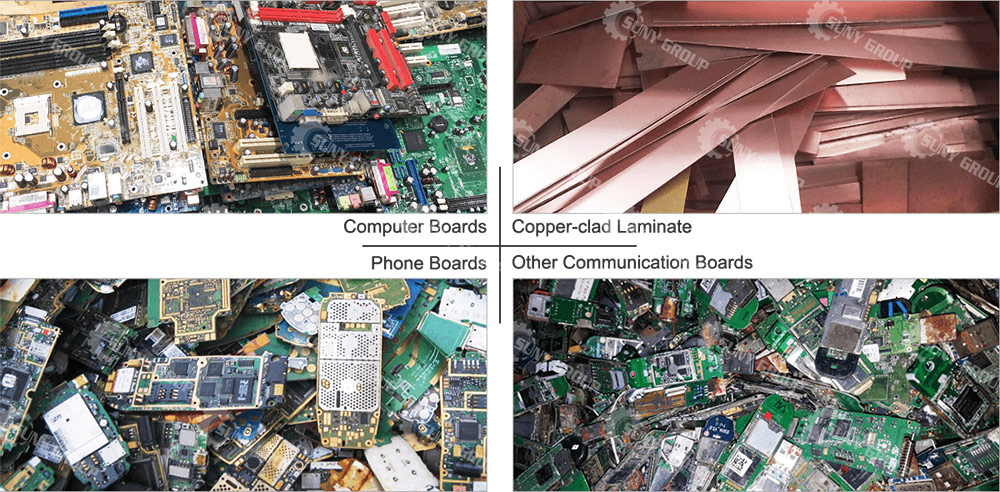

This machine is suitable for recycling all waste circuit board, copper clad, leftover material, such as computer board, mobile phone board, TV board, etc.

The final product is metal powder and fiber powder, the separating purity can reach up to 99%.

Gallery

Working Process

Double Shaft Shredder: The process of coarse crushing requires a double-shaft shredder to shred the material.

Crusher Machine: Hammer crushing can effectively break up caked materials, and the discharging size is about 20 mm.

Multifunctional Grinder: The fine pulverize has a three-layer vibrating screen for fine, uniform powder output, and running in a fully enclosed, dust-free environment under negative pressure.

Separation Equipment:The airflow separator and electrostatic separator each conducted two rounds of separation for metal powder and fiber powder, achieving a high material recovery rate of 99% and an output purity of 99%.

Dust Collection System: The production line is equipped with 2 pulse dust collectors, which have high dust removal efficiency and can capture dust particles larger than 0.3 micrometers with an efficiency of up to 99%.

Utilizing PLC Control: Continuous feeding, intelligent operation, automatic alarms, bilingual interface, easy and efficient operation, ensuring stable equipment operation.

Features

1. Suitable structure and layout, stable performance and recycling water is used to control temperature and reduce noise in the grinder;

2. PLC system makes it easier to control the whole line, the negative pressure feeding system prevent the dust from running out;

3. Feedback system makes the grind much more effective;

4. The separation rate of air separator can reach 97% and the separation rate of pulse dust cleaning device can reach 99%;

5. Electrostatic separator makes higher and quicker separation, moreover gets more non-ferrous metal;

6. With the magnetic separator ,the iron can be separated from other metals.

Sepcifications

| Model | Capacity | Power | Weight | Size(m) |

| PCB150 | 100-150kg/h | 110kw | 7.5ton | 12x6x5 |

| PCB300 | 200-300kg/h | 193kw | 15ton | 20x5x5 |

| PCB500 | 400-500kg/h | 242kw | 20ton | 25x6x5 |

| PCB1000 | 800-1000kg/h | 458kw | 40ton | 35x8x5 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

E Waste Recycling Plant

E Waste Recycling Plant

PCB Dismantling Machine

PCB Dismantling Machine

Precious Metal Refine Plant

Precious Metal Refine Plant

Gold Stripping Equipment

Gold Stripping Equipment