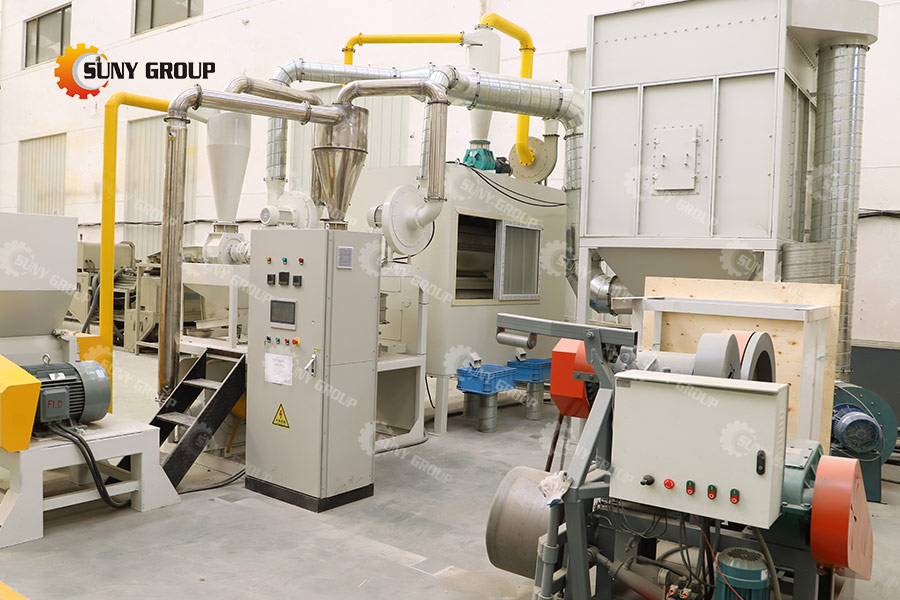

Aluminum plastic separation machine

Aluminum plastic separation machines play a crucial role in the recycling of aluminum-plastic composite materials, which are commonly found in packaging, medicine, and electronic waste. These materials, often difficult to recycle using traditional methods, can be efficiently processed using specialized machines, contributing to the circular economy and reducing landfill waste.

The main function of the aluminum plastic separation machine is to separate the aluminum from the plastic in composite materials, allowing for the recovery of both materials for reuse. The process typically begins with crushing the waste material, which can include items such as aluminum-plastic packaging or used medical blister packs. The shredded material is then fed into a separation system that uses a combination of airflow, vibration, and gravity separation.

One of the key features of the machine is its ability to handle various types of aluminum-plastic composites, such as those found in pharmaceutical packaging, beverage cartons, and cable insulation. By efficiently separating the aluminum and plastic, the machine ensures that both materials are clean and ready for reuse in the manufacturing process.

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Main application of mobile shredder machine

Main application of mobile shredder machine  Laminated glass separator equipment in Malaysia

Laminated glass separator equipment in Malaysia  Application of metal crushing recycling line

Application of metal crushing recycling line