Aluminum Plastic Separation Machine

-

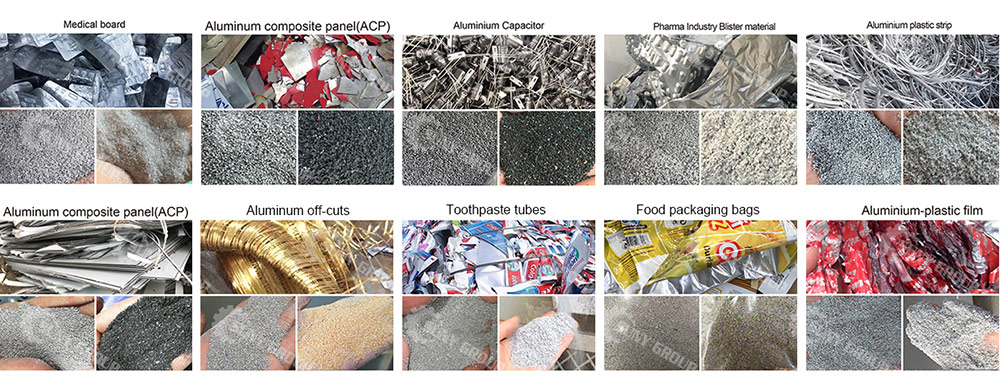

Aluminum-plastic separation and recycling equipment is designed to efficiently separate aluminum from plastic materials in products like pharmaceutical blisters, soft packing, aluminum tubes, aluminum-plastic bottle caps, aluminum-plastic plates. Using advanced mechanical and electrostatic technologies, it separates aluminum and plastic components with high precision. This equipment have great contribution to the circular economy and reducing waste in industries that produce aluminum-plastic composite materials.

Overview

The aluminum plastic separation machine is mainly used for the recycling and separation of various kinds of aluminum-contained materials such as pharmaceutical blisters, soft packing, aluminum tubes, aluminum-plastic bottle caps, aluminum-plastic plates and ACP(Aluminum composite panel). It can fully separate the aluminum and plastic.

Aluminium plastic separator adopts crushing, grinding, separating, dust removing technology process to achieve completely & simultaneously separating recycling aluminum metal and plastic powder.

Gallery

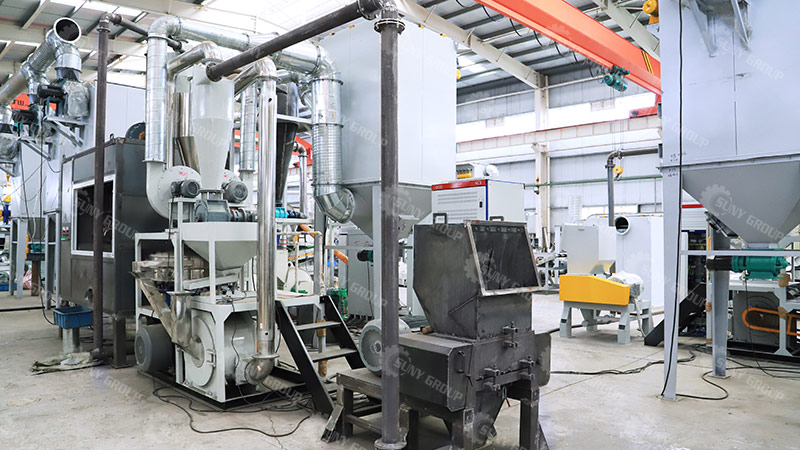

Working Process

The aluminum and plastic materials firstly crushed by the knife crusher into 10mm pieces, and then grinding by the water cooling turbo type grinding machine into aluminum and plastic fine powders. Then separated by the rotary screen, the big size will back into the grinding machine and the fine powders will into the electrostatic separator, finally the aluminum and plastic would be separated.

Features

1. Negative pressure

The whole recovery process is a sealed negative pressure environment, which reduces the emission of gas and pollutants.

2. No pollution

The recovery production line is equipped with a dust removal system, and the gas and particulate matter are collected and treated by the dust removal system and discharged up to the standard.

3. Safety

Many parts of the production line are equipped with detection facilities such as temperature and cyclopentane gas concentration, and graded alarm and safety control are carried out.

4. Automation

The refrigerator production line is equipped with an intelligent automatic control system, which adopts man-machine isolation operation mode, monitors the system in real time through the monitoring screen, and keeps abreast of the equipment operation.

Sepcifications

| Model | Capacity | Power | Size(MM) |

| APR-300 | 200-300kg/h | 125kw | 9000*7500*5000 |

| APR-500 | 400-500kg/h | 270kw | 18000*9300*5000 |

-

Contact Us

HAVE QUESTIONS?

Leave your details and we will reply to your message in 24 hours.

GET IN TOUCH! -

Aluminum Plastic Separation Machine

Aluminum Plastic Separation Machine

ACP Recycling Plant

ACP Recycling Plant